A ttha tein suaimi Flange phun Ductile Iron PN10/16 Thli Chuahnak Valve

A tthangcho bikmi thil sernak seh, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak zohkhenhnak system le hawikomhnak a ngeimi thiamsang zuarnak phu zuar hlan/hnu bawmhnak kan ngei.Thli Chuahnak Valve, Chawlehthalnak karhternak caah, tinhmi a ngeimi pumpak le bawmchantu hna kha agent rian ttuan dingin lungtak tein kan sawm hna.

A tthangcho bikmi thil sernak seh, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak zohkhenhnak system le hawikomhnak a ngeimi specialist gross sales team zong zuar hlan/hnu ah bawmhnak kan ngeiThli Chuahnak Valve, “Tthatnak cu a hmasa bik a si, Technology cu hrampi a si, dinfelnak le thilthar sernak” timi hruainak phunglam kha kan dirpi zungzal. Kannih cu thilri thar pawl kha a sang deuhmi dirhmun tiang pehzulh tein kan ser khawh hna i cu nih cun a phunphun in a herhmi thilri pawl kha a tlinter khawh hna.

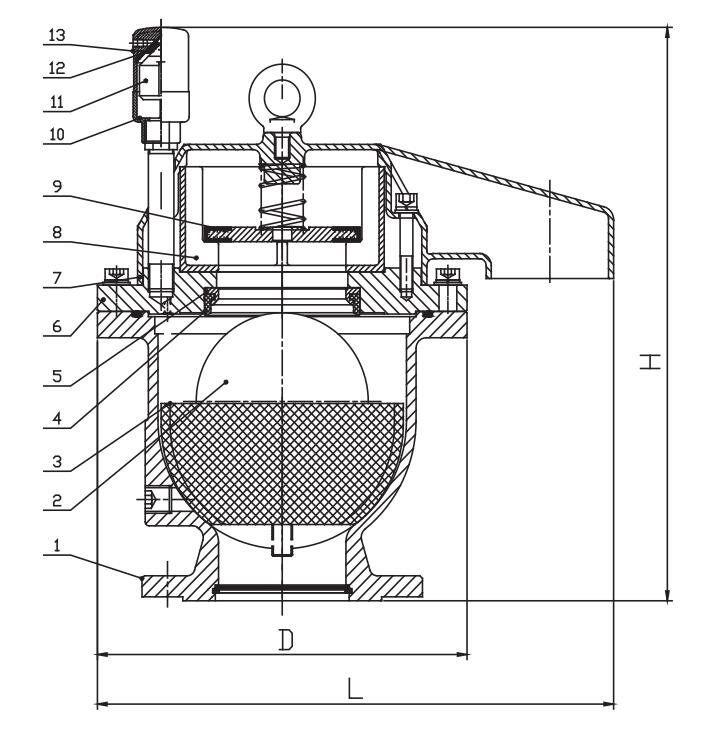

Langhtermi:

A rang tukmi thli chuahnak valve cu a sangmi diaphragm thli valve tthen hnih le a niammi luhnak le chuahnak valve he fonh an si, a chuahnak le a luhnak riantuannak pahnih a ngei.

A tthawngmi diaphragm thli chuahnak valve nih pipeline cu pressure tangah a um tikah pipeline chung i a khonmi thli tlawmte kha amah tein a chuahter.

A tlawmmi hneknak laknak le chuahnak valve nih a lawngmi pipe cu ti in a khat tikah pipe chung thli kha a chuahter khawh lawng si loin, pipe cu a thiang lo asiloah a ttha lomi hneknak a chuah tikah, ti column tthennak dirhmun tangah tibantuk ah, amah tein aa hun lai i a ttha lomi hneknak kha hloh awkah pipe chungah a lut lai.

Riantuannak caah a herhmi:

A tlawmmi thli chuahnak valve (float + float phun) thli chuahnak hmun nganpi nih thli cu a rang tukmi thli chuahnak ah a lut i a chuah khawhnak hnga a tuah, a rang tukmi thli chuahnak hmanh ah ti thli he cawhmi, thli chuahnak hmun kha a hlankan in a khar lai lo. Vanlawng chuahnak hmun cu thli a chuah dih hnu lawngah khar a si lai.

Zeitik caan paoh ah, system chunglei hneknak cu thli hneknak nakin a niam deuh chung paoh cu, tahchunhnak ah, ti tthennak a chuah tikah, thli valve cu system chung i thli luhter awkah a hun colh lai i cu nih cun system chung i vacuum a chuahter lai lo. Cu lio caan te ah cun, system a thlet lio ah thli a caan hmaan tein laknak nih thli chuah rangnak a rangter khawh. Exhaust valve cunglei cu exhaust kalning a nemtertu dingah a hnahnawhnak a kham khomi tlawmpal he aa thuam, cu nih cun pressure aa thleng lengmangmi asiloah a dang rawhralnak thil a kham khawh.

A tanglei thil sining hna hrial khawhnak dingah system chung i a sangmi hmun ah a tlummi thli kha system cu pressure tangah a um lio ah a chuahter khawh: thli kharnak asiloah thli kharnak.

System lu tlaunak karhternak nih a luannak a zorter i a zual tukmi thil sining hmanh ah ti phorhnak kha a dihlak in a ngolter khawh. Cavitation rawhralnak kha fak deuh in tuah, thir thilri hna i rawhnak kha rang deuh in tuah, system chung i pressure thlennak kha karhter, tahnak thilri palhnak kha karhter, le gas puahnak kha karhter. Pipeline riantuannak ah ti peknak tthatnak tthanchoter.

Riantuannak phunglam:

A lawngmi pipe cu ti in a khat tikah fonhmi thli valve riantuan ning:

1. Ti tling tein a kal khawh nakhnga pipe chung thli kha chuah.

2. Pipeline chung i thli cu a dih hnu ah, ti cu a niammi luhnak le chuahnak valve ah a lut, cun a luhnak le chuahnak hmun pawl kha khar awkah a luangmi nih a cawi.

3. Ti pekchanhnak tuah lio ah ti chungin a chuakmi thli cu system a sang bik hmun ah lak a si lai, cucu, thli valve chungah valve pum chung i a hramthawk ti aiawhtu ah lak a si lai.

4. Thli a khon tikah, a sangmi micro automatic chuahnak valve chung i ti tlawmtam cu a tla, cun a luangmi ball zong a tla ve, diaphragm kha khar awkah a hnuh, thli chuahnak khaan kha a hun i thli kha a chuahter.

5. Thli a chuah hnu ah, ti cu a fakmi micro-automatic chuahnak valve chungah a lut ṭhan, a luangmi ball kha a hler, cun thli chuahnak khar kha a khar.

System a kal lio ah, a cunglei 3, 4, 5 step pawl cu a kal peng lai

System chung i a ummi hneknak cu a niam i thli hneknak (negative pressure a chuahtertu) a si tikah fonhmi thli valve riantuan ning:

1. A tlawmmi thli luhnak le chuahnak valve i a luangmi ball cu a tla colh lai i luhnak le chuahnak port pawl kha a hun lai.

2. Hi hmun in thli cu a ttha lomi hneknak hloh awk le system kilven awkah system chungah a lut.

A kauh ning:

| Thilri phun | TWS-GPQW4X-16Q | |||||

| DN(mm) | DN50 | DN80 | DN100 | DN150 | DN200 | |

| Kauhning (mm) | D | 220 | 248 | 290 | 350 | 400 |

| L | 287 | 339 | 405 | 500 | 580 | |

| H | 330 | 385 | 435 | 518 | 585 | |

A tthangcho bikmi thil sernak seh, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak zohkhenhnak system le hawikomhnak a ngeimi thiamsang zuarnak phu zuar hlan/hnu bawmhnak caah kan ngei. hitch cu agent pakhat bantuk in.

A ttha tein suaimi thli chuahnak valve, “Tthatnak cu a hmasa bik a si, thiamnak cu hrampi a si, dinfelnak le thilthar sernak” timi hruainak phunglam kha kan dirpi zungzal. Kannih cu thil thar pawl kha a sang deuhmi dirhmun tiang pehzulh tein kan ser khawh hna i cu nih cun a phunphun in a herhmi thilri pawl kha a tlinter khawh hna.