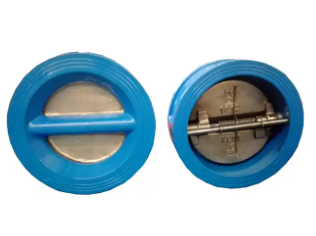

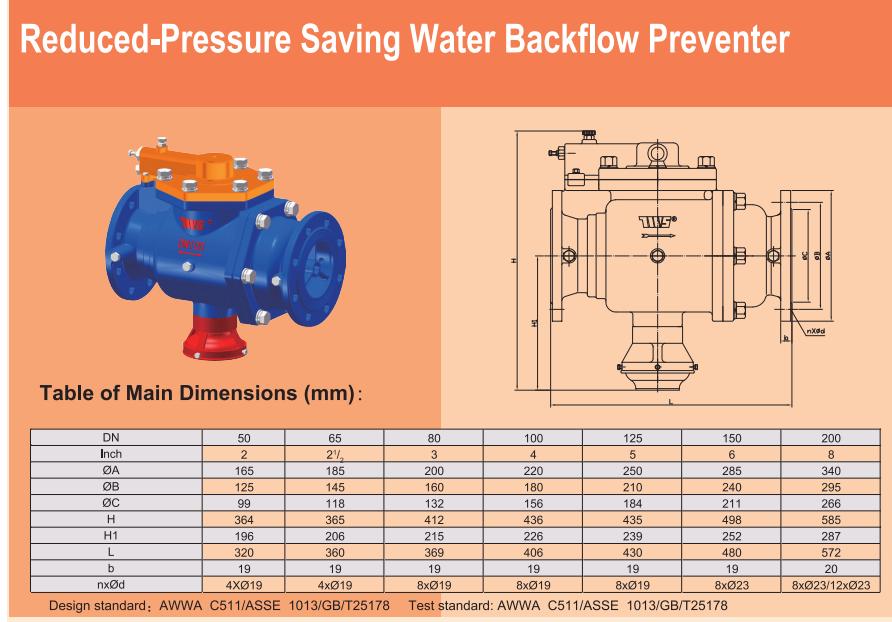

Tlawmpal Doh khawhnak DN50-400 PN16 A kir tthan lomi A tthawngmi Thir Flange phun Backflow Preventer

Kan i tinh bikmi cu kan riantuan hawi hna kha a fekmi le ttuanvo a ngeimi chawlehthalnak pehtlaihnak pek ding a si awk a si, an dihlak in Slight Resistance Non-Return Ductile Iron caah pumpak zohkhenhnak pek ding a si awk a siBackflow khamnak, Kan company nih “customer hmasa” kha a pek i customers pawl kha an chawlehnak kauhter awkah bawmh awkah bia a khiah, cucaah annih cu Big Boss an si khawh nakhnga !

Kan i tinh bikmi cu kan riantuanpi hawi hna kha a biapimi le ttuanvo a ngeimi chawlehthalnak pehtlaihnak pek ding a si awk a si, an dihlak in pumpak zohkhenhnak pek ding a si awk a siFlanged Type Backflow Preventer, Kan thilri pawl cu hmantu hna nih an cohlan i an zumh i aa thleng lengmangmi sipuazi le zatlang herhbaunak kha an tlinh khawh. Hmailei chawlehnak pehtlaihnak le pakhat le pakhat hlawhtlinnak caah kanmah he pehtlaihnak tuah dingin nunphung kip in a thar le a hlunmi riantuanpi hawi hna kha kan in don hna!

Langhtermi:

Kan dothlennakhnulei luannak khamnak– na ti chuahnak kha a chuak khomi thurhnawmhnak ttihnung in kilvennak caah a ttha ngaimi a phichuak. An suaisam ning le thilthar sernak hna he, kan hnulei luannak khamnak nih na umnak hmun asiloah chawlehnak hmun ah a thiangmi, a himmi ti kha pehzulh tein, hnahnawhnak um loin a pek khawh.

Backflow preventer rian nganbik cu ti a kir tthanmi ngolter le thil thurhnawm asiloah thil thurhnawm pawl kha ti line nganpi chung luh lonak ding caah a si. Cu nih cun dawnkhantu rian a ttuan, na dinmi ti kha chemical, bacteria, asiloah pipe chungah a kir khomi thil thurhnawm dangdang hna in a huhphenh. Kan backflow khamnak thilri hna cu ti chuahnak thianhlimnak a kilvengtu le na chungkhar, riantuantu asiloah na cawtu hna ngandamnak le himnak a kilvengtu zumhawktlak le a herhmi thilri an si.

Hi valve pawl nih hin hnulei a luannak khamnak caah a pahnih in khamnak an pek. Valve pakhat a rawh ahcun, valve dang pakhat a rian a ttuan, cu nih cun system a tthatnak a kilven. Valve pakhat cio cu ralring tein suaimi le riantuannak phunglam le phunglam hna he aa tlak khawh nakhnga fakpi in hneksaknak an tuah. A ttha ngaimi thilri in sermi, kan hnulei luannak khamnak hna cu a fekmi le caan sau a hmunmi an si, lungretheihnak um loin kum tampi chung riantuan khawhnak a kan pek.

Hmunhma cu a sawhsawh i a fawi i a thar asiloah a um cangmi pipe system ah fawi tein fonh khawh a si. Kanmahhnulei luannak khamnakzohkhenhnak tlawm deuh in sermi an si, cu nih cun zohkhenhnak le remhnak tuah lengmang a herhnak a zorter. A hmete le aa dawh ngaimi suaisam nih hmunhma tlawmte lawng a herhter, innchung le lenglei chiahnak caah aa tlak.

Kan ti luannak khamnak thilri hna he, na ti system cu a chuak khomi ttihnung thil vialte in huhphenh a si lai ti kha na zumh khawh. Inn ngeitu na si zongah, chawlehnak ngeitu na si zongah, thilri zohkhenhtu na si zongah, kan thilri hna cu na ti luhchuahnak thilri caah a herhmi chapmi an si. Na ti laknak ah aa tluk lomi riantuan ning, zumhawktlak sinak le himnak a pek khawh nakhnga kan backflow khamnak thilri pawl kha zum hna.

Mah sining a langhtertu:

1. A tlawm i a tawi; dohnak tlawmpal; ti khonnak (a ttha mi ti chuahnak thli thlennak ah a ttha lomi ti chuahnak thil a um lo); a him (a cunglei ti peknak system ah a ttha lomi thli a tlau tikah, ti chuahnak valve cu a caan te ah on khawh a si, a thiang kho, cun hnulei luannak khamnak a laifang khur cu thli tthennak ah a cunglei nakin a biapi deuh zungzal); on-line hmuh khawhnak le zohkhenhnak tbk. Sipuazi luannak ah a ttha mi riantuannak tangah, thilri suaisamnak ti nih a hrawhmi cu 1.8~ 2.5 m a si.

2. Two level check valve's a kau ngaimi valve cavity luannak suaisam cu luannak doh khawhnak hmete, check valve rang tein on-off seals a si, cu nih cun valve le pipe rawhnak kha ruahlopi in a sangmi hnulei hneknak nih a kham khawh, aw chuah lonak riantuannak he, valve riantuannak nunnak kha ttha tein a sauter khawh.

3. Ti chuahnak valve a dikthliar in suaisam, ti chuahnak thli nih a tthenmi ti peknak system i thli thlennak man kha a remh khawh, cu nih cun system thli thlennak hna kha a hrial khawh. Himnak le zumhawktlak tein on-off, a ttha lomi ti a luannak a um lo.

4. A nganmi diaphragm uknak khur suaisam nih a biapimi thilri hna i zumhawktlak sinak kha a dang backlow khamnak nakin a ttha deuhter, him tein le zumhawktlak tein on-off caah drain valve caah.

5. A kau ngaimi ti chuahnak onnak le thlennak lam, valve kuang chung i aa pehtlaimi luhnak le ti chuahnak fonhmi dirhmun nih ti chuahnak kongah buainak a ngei lo, a hnulei ah a kir khawhnak kha a kham dih i siphon luannak thlennak a chuak.

6. Minung nih an sermi suaisam cu online in hneksaknak le zohkhenhnak a si kho.

Soknak:

A ttihnungmi thurhnawmhnak le ceunak thurhnawmhnak ah hman khawh a si, rungrul thurhnawmhnak caah, thli thleidannak in a kir tthanmi a kham khawh lo ahcun hman khawh a si;

A ttihnungmi thurhnawmhnak le pehzulh tein hneknak a luannak ah branch pipe hrampi ah hman khawh a si, cun a hnulei kirnak khamnak ah hman khawh a si lo

thurhnawmhnak.

A kauh ning:

Kan i tinh bikmi cu kan riantuanpi hawi hna kha a fekmi le ttuanvo a ngeimi riantuannak pehtlaihnak pek ding a si awk a si, an dihlak in Slight Resistance Non-Return Ductile Iron Backflow Preventer caah pumpak zohkhenhnak pek ding a si. Kan company nih “customer hmasa bik” kha a pek hna i customers pawl kha an chawlehnak kauhter ding in bawmhchanh ding in bia a khiah, cucaah annih cu Big Bos an si khawh lai!

Kan i tinh bikmi cu kan riantuanpi hawi hna kha a fekmi le ttuanvo a ngeimi riantuannak pehtlaihnak pek ding a si awk a si, an dihlak in Slight Resistance Non-Return Ductile Iron Backflow Preventer caah pumpak zohkhenhnak pek ding a si. Kan company nih “customer hmasa bik” kha a pek hna i customers pawl kha an chawlehnak kauhter ding in bawmhchanh ding in bia a khiah, cucaah annih cu Big Bos an si khawh lai!

Flanged Type Backflow Preventer, Kan thilri pawl cu hmantu hna nih an cohlan i an zumh i aa thleng lengmangmi sipuazi le zatlang herhbaunak kha an tlinh khawh. Hmailei chawlehnak pehtlaihnak le pakhat le pakhat hlawhtlinnak caah kanmah he pehtlaihnak tuah dingin nunphung kip in a thar le a hlunmi riantuanpi hawi hna kha kan in don hna!