Zei dah a sivalvecavitation? Zeitindah hloh khawh a si?

Tianjin Tanggu Ti-Seal Valve Co., Ltd

Tianjin,CHINA

19nak,June thla,2023

Aw nih minung pum cungah a chiatnak lei in hnahnawhnak a pek khawh bantukin, control valve kha ttha tein thim a si tikah frequency cheukhat nih riantuannak thilri cungah rawhralnak a chuahter khawh, cavitation a chuahter khomi a karh, cu nih cun aw-an le hninhnak a chuahter lai, cu nih cun a chunglei le a tanglei pipe pawl kha rang tukin a hrawh hna laivalve.

Cun, aw-an sang nih pipe, thilri le thilri dangdang a hrawh khomi hninhnak a chuahter tawnValvecaan a liam thluahmah tikah, thilri pawl rawhnak, pipeline system nih a chuahtermi valve cavitation nih fakpi in rawhralnak a chuahter. Hi rawhralnak hi a tam deuh cu hninhnak aw-an thazaang, a rangmi rawkralnak kalning le a tlawmmi pawng le a tanglei ah a ummi steam bubbles sernak le rawhnak nih a chuahtermi a nganmi amplitude hninhnak aw-an sang nih a langhtermi cavitation nih a chuahtermi a si.

Mah cu ball ah a cang tawn ko nainvalvesle pum chung i aa mer khomi valve hna, V-ball i wafer pum tthen he aa lo in a tawimi, a sangmi tthanchonak ah a cang kho taktakvalve, a hlei inbutterfly valvesvalve tanglei lei ah a si tikahvalvecavitation phenomenon a chuahter khomi hmun pakhat ah a buai, cucu valve piping le welding remhnak ah a luang khomi a si, valve cu hi line tthen caah aa tlak lo.

Valve chung ah siseh, valve tanglei ah siseh, cavitation a chuah zongah, cavitation hmun i thilri hna cu a tlawm tukmi zukcawl, springs le a hmete mi cantilever structures hna caah rawhralnak nganpi an tong lai, a nganmi hninhnak nih hninhnonak a chuahter khawh. A caancaan ah a tlamtlin lonak hmun cu thilri hna ah hmuh khawh a si, cu hna cu pressure gauge, transmitter, thermocouple sleeves, flowmeters, sampling systems hna an si.

Hninhnak a tongmi a rawkmi vawlei karlak ah a cangmi fretting corrosion cu cavitation valve pawng ah a um tawn. Mah nih hin a rawkmi thilri karlak ah rawhnak a rangtertu dingah a harmi oxides a chuahter. A tlunhmi thilri hna ah hin thleidannak le zohfelnak valve hna an i tel, cu pin ah control valve, pump, aa mer khomi screen, sampler le a dang aa mer khomi asiloah a tlikmi thilri hna an i tel.

A fakmi hninhnak nih thir valve tthen le pipe vampang zong a hrawh khawh i a hrawh khawh. A tthencheu mi thir tlawmpal asiloah a rawk khomi chemical thilri nih pipeline chung i media kha a thurhnawmh khawh, cu nih cun thianhlimnak valve piping le a thiangmi pipe media cungah tampi hnahnawhnak a pek khawh. Mah zong hi a ngah lo.

Plug valve hna i cavitation tlamtlin lonak chimchungnak cu a har deuh i tuaktanmi choke pressure tlaknak sawhsawh a si lo. Hmuhtonnak nih a langhter ning ahcun, cuka hmun i a ummi thlihrannak le thlihrannak bubble a rawhnak hlan ah a tlangpi in a luangmi thlihrannak cu ti thlihrannak thlihrannak tiang a tla kho men. Valve sertu cheukhat nih a hramthawk rawhralnak ttumchuknak fianternak in a caan hlan ah ni tlaknak rawhralnak kha an chimchung. Valve sertu nih cavitation rawhralnak chimchungnak in an thawk ning cu steam bubbles a rawk i, cavitation le aw a chuahter timi cungah hram aa bunh. Tuakmi aw-an cu a tanglei ah langhtermi ri tang ah a um ahcun a nganmi cavitation rawhralnak cu hrial khawh a si lai tiah biakhiahnak tuah a si cang.

Valve ngan cu 3 inches tiang – 80 dB

Valve ngan cu 4-6 inches – 85 dB

Valve ngan le hme 8-14 inches – 90 dB

Valve ngan le hme 16 inches le a ngan deuh – 95 dB

Cavitation rawhralnak hloh khawhnak lam hna

Cavitation hloh khawhnak ding caah a hleiin sermi valve suaisam nih a cheu mi luannak le a tlawm deuhmi hneknak a hman:

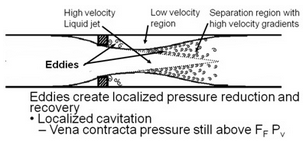

"Valve thlennak" cu a luangmi luannak nganpi kha a luannak hme tete ah tthen a si, cun valve a luannak lam cu a luannak cu aa tlukmi a hmete a ongmi tampi chungin a luan khawhnak ding caah suaimi a si. Zeicatiah cavitation bubble a ngan ning cheukhat cu a luannak a ongnak in tuak a si. A hme deuhmi onnak nih bubble hmete a chuahter, cu nih cun aw-an a tlawmter i rawhralnak a chuahter tikah rawhralnak a tlawmter.

“Graded pressure drop” timi cu valve cu aa pehtlaimi thlennak hmun pahnih asiloah a tam deuh ngeih dingin sermi a si, cucaah pressure tlaknak dihlak kha step pakhat ah tuah loin, step hme deuh zeimawzat a lak. Mi pakhat cio nih an ttumnak tlawm deuh nih cun a ttumchuknak ah a tlawm deuhmi tthawnnak kha a kham khawh, cucaah valve chung i cavitation thil cangmi kha a hloh khawh.

Valve pakhat chung i thlennak le pressure drop staging fonhmi nih cavitation doh khawhnak a tthanchoter. Valve remhnak lio ah, control valve chiah le valve luhnak ah a ummi hneknak cu a sang deuh (tahchunhnak ah, a cunglei lei ah, asiloah a niam deuhnak hmun ah), a caan ah cavitation buainak a hloh.

Cun, control valve kha ti lumnak hmun ah chiah, cucaah a niammi meikhu hneknak (a niammi lumnak lei lumnak thlennak tibantuk) nih cavitation buainak kha a hloh khawh.

A tawinak in a langhter mi cu valve hna i an cavitation phenomenon cu a rawkralnak riantuannak le valve hna i rawhnak lawng si loin a si taktak. A tanglei pipeline le thilri pawl zong tihnung an si. Cavitation chimchung le hloh khawhnak ding caah thil tuah cu a man a fakmi valve hmannak dihmi buainak hrial khawhnak lam pakhat lawng a si.

Post caan: Jun-25-2023