Butterfly valve phun tampi a um, cun thleidannak lam tampi a um.

1. Dirhmun ning in tthencheunak

(1)aa khatmi hlinghro valve; (2) pakhat lawng a ummi butterfly valve; (3) pahnih-aa thleidangmi hlinghro valve; (4) a dang tein a ummi hlinghro valve pathum

2. A kharnak thilri ning in tthencheunak

(1) A fekmi hlinghro valve

(2) Thir phun a fekmi kharmi hlinghro valve. Sealing pair cu thir a harmi thilri in thir a harmi thilri in sermi a si.

3. Sealed form in tthencheunak

(1) Hramhram in kharmi hlinghro valve.

(2) Hnawmhnak kharnak butterfly valve. Seal pressure cu tthutnak asiloah plate cung i a ummi elastic sealing element nih a chuahter.

(3) Amah tein aa kharmi hlinghro valve. Seal a bik in hneknak cu a tlawm deuhmi hneknak nih amah tein a chuahter.

4. Riantuannak hneknak in tthencheunak

(1) Vacuum butterfly valve. A tlangpi thli nakin a niam deuhmi riantuannak thli he butterfly valve.

(2) A niam deuhmi butterfly valve. PN≤1.6MPa a tlawmmi hneknak he butterfly valve.

(3) A tlawm deuhmi hneknak valve. A min in a ummi hneknak PN cu 2.5∽6.4MPa a simi butterfly valve a si.

(4) A tthawngmi hlinghro valve. A min in hmanmi hneknak PN cu 10.0∽80.OMPa a simi butterfly valve a si.

(5) A sang tukmi hneknak butterfly valve. Butterfly valve cu a tlawmbik PN <100MPa a ngeimi a si.

5. Pehtlaihnak ning in tthencheunak

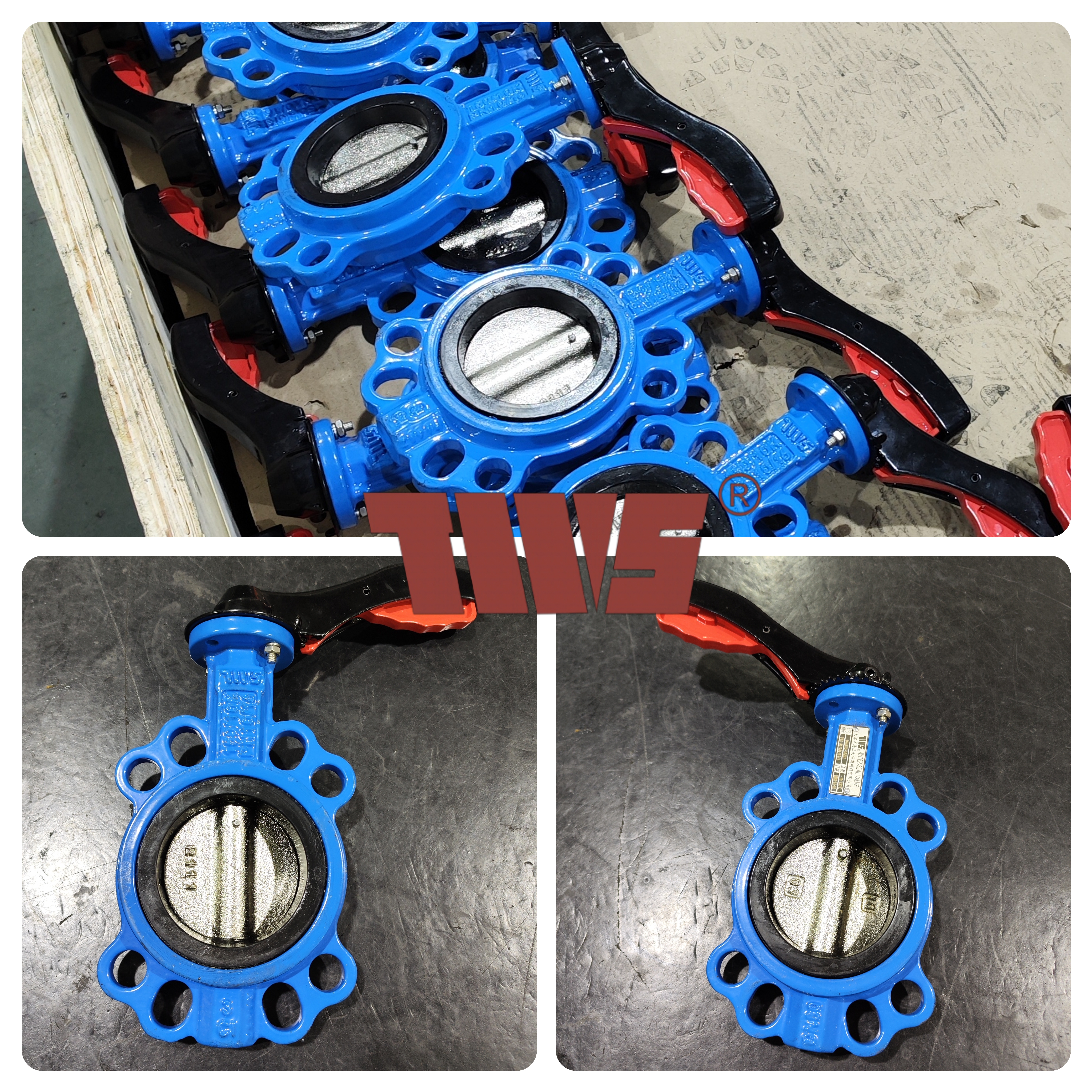

(1)Wafer butterfly valve

(2) Flange butterfly valve

(3) Lug butterfly valve

(4) Welded butterfly valve

Concentric Butterfly valve cu a tlongmi butterfly plate in aa hun i a kharmi valve phunkhat a si i valve hnah aa mer tikah ti kalnak lam kha a hun, a khar i a remh. Butterfly valve i butterfly plate cu pipe diameter lei ah chiah a si. Butterfly valve pum i a tlongmi lam ah, disc butterfly plate cu axis pawng ah aa mer, cun aa mernak angle cu 0 le 90 karlak ah a um. A mernak 90 a phak tikah, valve cu a tling tein aa on.

Saknak le chiahnak ah a biapimi hmun hna

1) Chiahnak hmun, a sannak, luhternak le chuahnak lam cu suaisam ningcang he aa tlak a hau, cun pehtlaihnak cu a fekmi le a fekmi a si awk a si.

2) Lungthawhnak khamnak pipe cung ah chiahmi kut in tuahmi valve phunkip hna i an kutka cu a tanglei lei ah a um awk a si lo.

3) Valve cu chiah hlan ah lenglei in zohfel a hau, cun valve min cazin cu atu lio ram pumpi phunglam “General Valve Mark” GB 12220 phunglam he aa tlak a hau. 1.0 MPa nak tam deuh riantuannak thazaang a ngeimi le main pipe ah a tthenmi valve caah cun, chiah hlan ah a fekmi le a fekmi riantuan ning hneksaknak tuah a si lai i hman dih hnu ah hman a si lai. Thazaang hneksaknak ah, hneksaknak hneknak cu a min hneknak nakin a let 1.5 a si, cun a sauh ning cu 5min nak tlawm lo a si. Valve shell le packing cu a luannak um loin aa tlakmi a si awk a si. Tightness hneksaknak caah, hneksaknak hneknak cu a min hneknak nakin a let 1.1 a si; hneksaknak caan chung vialte hneksaknak thli nih GB 50243 phunglam a tlinh lai, cun valve kharnak cunglei cu aa tlak.

A biapi bikmi thilri thimnak

1. Butterfly valve i a biapi bikmi uknak parameters cu a sining le a kauhning hna an si.

2. Butterfly valve cu thli valve pakhat lawng a si, a sining a sawhsawh, tuah a fawi, a man a fawi, hman a fawi, asinain remhnak a dikthliar lo, thli luhchuahnak le thli lumternak system caah aa tlakmi asiloah caan thlennak caah a tlawmmi remhnak caah lawng aa tlak.

3. Kut in, electric asiloah zipper phun in hman khawh a si, zeibantuk Angle 90 karlak ah remh khawh a si.

4. Single axial single valve plate ruangah, bearing force cu a tlawm, pressure thleidannak nganpi dirhmun ah, valve riantuannak caan a tawi tikah a luannak rate nganpi a um. Valve cu kharmi phun le a tlangpi phun, khamnak le khamnak a si lomi a ngei.

5. Electric butterfly valve nih hin dual type control lawng a ngei, electric actuator cu multi-leaf valve he aa khat.

Post caan: Oct-26-2023