Hmannak caah a dikmi seal thilri thim tikah ruah awk a biapi mi thil cheukhat cu zeidah an si?

A man a ttha i aa tlakmi rong

Seal hmuh khawhnak

Sealing system ah a thlentu thil vialte: tahchunhnak ah lum le lum lo, ti le hneknak

Hi vialte hi na kharnak system ah ruah awk a biapi mi thil an si. A ruang vialte hngalh dih a si ahcun, a hmaanmi thilri thim a fawi lai.

Asinain a herhmi cu thilri cu a fekmi a si awk a si. Cucaah ruah hmasa dingmi cu thiamnak lei riantuan ning a si. Riantuannak lei in thawk hna usih.

System nunchung le man cu a biapi mi thil an si (TIanjin Tanggu Water-Seal Valve Co.,ltd) ruah awk. Thil vialte nih na application riantuan ning a hnorsuan lai. Application ning in suaisamnak kong ruah a biapi. Mah ah hmanmi thilri, thilri hmete le thilchuah ningcang hna aa tel. Pawngkam thil zong ruah awk a um, cu hna cu: hneknak, lumternak, caan, fonhnak le media hna an si.

elastomer

Elastomers cu an tthawngmi an si caah an lar. A dang thilri pakhat hmanh nih a tluk tein a tthawnnak a ngei lo.

Polyurethanes le thermoplastics tibantuk thilri dang hna cu elastomers nakin hneknak an tuar khawh deuh.

Rubber thilri pawl cu hmannak phunphun ah hman khawh an si.

A biapi mi seh thilri hna ah aa tel

tthawnnak

harnak

hnuh khawhnak thazaang

A dang a biapimi thilri hna cu

•Compression set

•lumnak doh khawhnak

•tlawmte lumternak thlen khawhnak

•chemical he aa tlaknak

•Tarnak dohnak

•hnahnawhnak doh khawhnak

A biapi bikmi cu rubber thilri a tthawnnak a si. Mah kong hi tam deuh in cawng hna u sih.

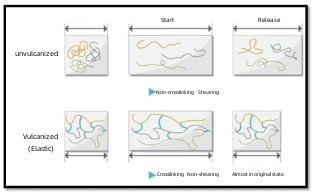

Elasticity cu vulcanization nih a chuahpimi a si. Elastomeric thilri, vulcanized rubber tibantuk hna cu an rawk ahcun an sining taktak ah an kir than lai.

A tthawng lomi thilri, unvulcanized rubber tibantuk hna cu an rawk ahcun an dirhmun ah an kir ti lai lo. Vulcanization (cu bantukflange pahnih a ummi butterfly valve) cu rubber kha elastomeric thilri ah thlennak kalning a si.

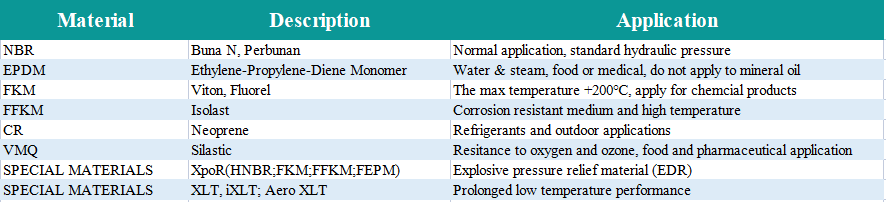

Elastomers thimnak cu a bik in:

•riantuannak lumnak tlukruannak

•Ti le thli hna doh khawhnak

•Khuacaan thlennak, ozone le UV ceunak doh khawhnak

Elastomers thimnak cu a bik in:

•riantuannak lumnak tlukruannak

•Ti le thli hna doh khawhnak

•Khuacaan thlennak, ozone le UV ceunak doh khawhnak

Valve kharnak thilri thim tikah ruah a herhmi thil paruk

A kharnak hmun cu a biapi bikmi riantuannak hmun a sivalve, kharnak cunglei tthatnak nih riantuannak nunchung kha direct in a hnorsuanvalve, cun kharnak cunglei thilri cu kharnak cunglei tthatnak hngalh khawhnak ding caah a biapi tukmi thil pakhat a si. Cucaah, valve kharnak thilri thim tikah a tanglei thil hna hi ruah chih ding an si:

①Rawkralnak doh khawhnak. “Corrosion” timi cu thilri nih a tuahmi thil ruangah kharnak cunglei a rawhnak a si. Sealing cunglei cunglei cu a rawk ahcun, sealing riantuannak cu zumh khawh a si lo, cucaah sealing cunglei thilri cu rawkralnak a tei khomi a si a hau. Thilri pakhatkhat i a rawkralnak doh khawhnak cu thilri chung i a ummi thilri le a chemical fekmi cungah aa hngat.

②Hliamhma dohnak. “Scratch” timi nih hin sealing surface aa pehtlaimi cawlcanghnak chungah thilri nih a chuahpimi rawhralnak kha a chim duhmi a si. Hi bantuk rawhnak nih hin kharnak cunglei kha a hrawh hrimhrim lai. Cucaah, kharnak cunglei thilri cu a ttha mi hliah khawhnak a ngeih a hau, a hlei in gate valve caah. Thilri pakhatkhat nih a hliam khawhnak cu thilri chunglei sining nih a khiah tawn.

3Ti rawhnak doh khawhnak. “Erosion” cu a rang tukmi in a luangmi thilri nih a kharnak cunglei hrawhnak a si. Hi bantuk rawhnak cu lum le lum tuknak steam media ah hmanmi throttle valve le himnak valve ah a fiang deuh, cun kharnak riantuan ning rawhnak ah tampi hnahnawhnak a pek. Cucaah, vawlei rawhnak doh khawhnak zong hi vawlei cung thilri pawl kharnak caah a herhmi a biapi mi pakhat a si.

④A fahnak pakhatkhat a ngeih awk a si, cun a fahnak cu a hleiin riantuannak lumnak tangah a tla tuk lai.

⑤Sealing cunglei le pum thilri i a tlarimi kauhnak coefficient cu aa khat awk a si, cucu sealing ring dirhmun caah a biapi deuh, cucaah lumnak sang ah a hlei in hnahnawhnak le tthawnnak hrial khawh a si.

6A lin tukmi dirhmun tangah hman ahcun, a za tawk in anti-oxidation, lumnak thazaang dernak le lumnak tthawnnak kong he pehtlai in a um a hau.

Atu lio thil sining tangah, a cunglei herhmi tling tein a tlinhmi kharnak thilri hmuh a har. Valve phun le hmannak aa dangmi ningin thil cheukhat a herhmi tlinternak lawng ah kan lungthin kan pek khawh. Tahchunhnak ah, a rangmi media ah hmanmi valve pawl nih kharnak cunglei i a rawkralnak doh khawhnak a herhmi kha a hleiin an zoh awk a si; cun thilri nih a fekmi thurhnawmhnak a ngeih tikah, a har deuhmi kharnak cunglei thilri kha thim ding a si.

Post caan: Mar-08-2023