- Thilri thimnak

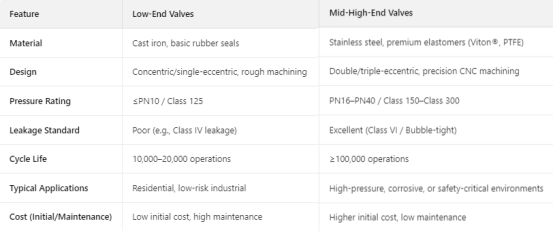

A niam deuhmi Valves

- Taksa/Disc thilri: A tlangpi in a man a fawimi thir hna kha hmangthirasiloah aa cawh lomi carbon thir, cu cu a harmi pawngkam ah rawkralnak a ngei lomi a si kho.

- Sealing Rings: A hrampi elastomer hna in sermiNR (natural rubber)asiloah a niam deuhmi EPDM, a tlawmmi chemical doh khawhnak le lumnak tuar khawhnak (tahchunhnak ah, ≤80°C / 176°F).

- Shaft: A cunglei thlopnak um loin carbon thir sawhsawh in sermi a si tawn, a lummi asiloah a almi hmun ah a rawk kho.

Mid-High-End Valves

- Taksa/Disc thilri: A ttha deuhmi thilri hna cu thir (SS304/316), a nemmi thir, asiloah aluminium dar tibantuk hna kha hmang hna law a ttha deuhmi rawhnak doh khawhnak le seh thazaang ngeih khawhnak caah.

- Sealing Rings: FDA-compliant EPDM, NBR, PTFE, asiloah Viton® tibantuk a ttha ngaimi elastomer pawl kha hmang,pekchanhnak broader chemical he aa tlak (tahchunhnak ah, chiti, acid, asiloah cawhnuk hna he aa ralchanh khomi) le a sang deuhmi lumnak (-20°C in 150°C / -4°F in 302°F tiang).

- Shaft: Thir (SS410/316) in sermi a si i a cunglei cu a tleu asiloah a thuh (tahchunhnak ah, nickel plating) he a rawkmi le a luangmi khamnak caah a si.

- Inn saknak suaisamnak le sernak

A niam deuhmi Valves

- A fawitermi suaisam: A tlawmmi kharnak tthatnak he a hrampi aa pehtlaimi asiloah aa pehtlaimi pakhat lawng a simi thilri hna. Disc le tthutdan cu a ttha lomi riantuannak an ngei kho, cu nih cun a sang deuhmi hnahnawhnak le thazaang a chuahter.

- I khawmhnak: A tlawm bik tthatnak uknak he tam deuh in chuah a si tawn, cu nih cun aa khat lomi tuar khawhnak a chuahter. A luangmi zat nih a fekmi phunglam a tlinh lo men lai (tahchunhnak ah, ANSI B16.104 Class VI herhmi a lonh).

- Hmannak:A tlangpi in a man a fawimi kut in hmanmi kutka asiloah a hrampi electric actuators he an i fonh, hman lengmang awkah a fekmi a ngei lo.

Mid-High-End Valves

- A sangmi suaisam: Hmaichung um thilaa dangmi pahnih asiloah aa dangmi pathum sininghnahnawhnak zorternak, kharnak tthatnak tthanchoternak le rawhnak tlawmternak caah. Tahchunhnak ah, aa dangmi pahnih suaisam nih a fek deuhmi kharnak caah "wedging effect" a ser.

- A dikthliar in sernak: A ttha ngaimi CNC thilri hmangin sermi, tluang tein disc cawlcanghnak le a ttha bikmi seal pehtlaihnak a tuah. A luangmi zat cu ISO 15848-1 (tahchunhnak ah, Bubble-tight Class A) a tlinh asiloah a lonh tawn.

- Riantuannak: A rangmi, a rangmi hmannak caah a sangmi actuators (pneumatic, hydraulic, asiloah fimthiamnak electric actuators) he aa tlak. Model cheukhat nih cun mah tein rian a ttuan khawhnak ding caah hmunhma chiahnak asiloah ruahnak cheuhnak hngalh khawhnak hna an i tel.

3. Riantuan ning le zumhawktlak sinak

A niam deuhmi Valves

- Pressure/Temperature Limits: A tlawmmi thlihrannak (tahchunhnak ah, ≤PN10 / Class 125) le lumnak tlawmte caah aa tlak. A lin tukmi (tahchunhnak ah, >PN16) asiloah a lin tukmi (-10°C in 90°C) pawngkam ah a rawk kho.

- Riantuannak Nun: Thilri fek lonak le suaisamnak palhnak ruangah a tawiter, zohkhenh asiloah thlen lengmang a herh (tahchunhnak ah, 10,000–20,000 cycles).

- A luannak ttihnung: Seal rawhnak asiloah shaft rawhnak a tam deuh, pawngkam ah a luangmi asiloah system rawhnak a chuahter.

Mid-High-End Valves

- Pressure/Temperature Limits: A tlawm-in-a sangmi hneknak system (tahchunhnak ah, PN16–PN40 / Class 150–Class 300) le a kau deuhmi lumnak (-30°C in 200°C / -22°F in 392°F) caah sermi a si.

- Riantuannak Nun: Caan sau zumhawktlak sinak caah sermi, riantuannak 100,000 leng a nunnak he. Cheukhat premium model nih cun nunchung hngatchannak an pek.

- A luangmi uknak: A tthangchomi seal le anti-blowout shafts nih a luannak ttihnung a zorter, cu nih cun gas system asiloah tihnung ti hmannak tibantuk a biapi tukmi hmannak caah aa tlakter hna.

4. Soknak

A niam deuhmi Valves

- Aa tlakmi: A biapi lomi, tihnung a tlawmmi hmannak hna he a hrampi luannak uknak herhmi, cu hna cu:

- Innchungkhar ti peknak system

- HVAC ductwork sawhsawh

- Tlawmte in ti thletnak asiloah ti chuahnak

- Hman hrial: A fakmi riantuannak pipeline, a rawk khomi media, asiloah himnak caah a biapi tukmi pawngkam (tahchunhnak ah, chiti le gas, sii).

Mid-High-End Valves

- A ttha bikmi: A harmi riantuannak le chawlehnak hmannak, aa telmi:

- Chemical sernak sehzung (a rawk khomi ti)

- Rawl le dinmi chuahnak (thianhlimnak phunglam)

- Thazaang chuahnak (a lum tukmi thli)

- Oil & gas (a puak kho lomi a herhmi)

- A Biapimi Phunglam: Ramkip himnak le tthatnak phunglam he aa tlak caah ISO, API, ASME, asiloah ATEX ah fehtermi a si tawn.

5. Man & Zohkhenhnak

A niam deuhmi Valves

- A hramthawk man: A man a fawi deuh (mid-high-end model nakin 20-50% tlawm deuh), cu nih cun tangka hmannak a tlawmmi project caah a ttha.

- Fim: Seal thlennak, shaft hriak, asiloah rawhnak remhnak ruangah caan saupi caah a dihmi a sang deuh.

- Caan dinh caan ttihnung: Ruahlopi in tlamtlin lonak a chuahter deuh, cu nih cun riantuannak hmun ah thilchuah sunghnak a chuahter.

A dikmi Valve thim (eg.TWS Valve)

- A niam bik: Caan tawite, a biapi lomi hmannak caah aa tlak, cuka ahcun man cu a biapi bikmi a si.

- Mid-High-End: A harmi hmannak ah zumhawktlak sinak, himnak le caan saupi riantuan khawhnak caah hi hna ah tangka chiah. Valve na thim tikah media phun, riantuan ningcang le zulhphung zulh a herhmi kha ruat zungzal.

Hi thleidannak nih hin zeicahdah mid-high-end valve pawl kha a langhterD371X-16Qhimnak le tthatnak biapi ah a chiahmi chawlehnak ah an duh deuh, cu lio ah a niam deuhmi thimnak nih a hrampi, man a fawimi herhmi a bawmh.

A nemmi kharnak, riantuannak a harmiwafer butterfly valve, Flange pahnih a ummi butterfly valve D34B1X-10Q, Gate valve, Y-strainer,Wafer dual plate check valve,-Leak Fredd thlennak caah sermi a si. A fekmi kharnak, aa tluk lomi zumhawktlaknak, na luannak uknak thiamsang.

Post caan: Jun-07-2025