1. Dirhmun hlathlainak

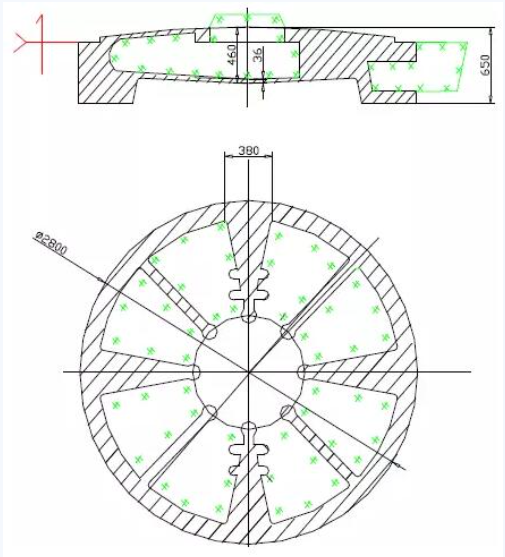

(1) Hihibutterfly valvea tlongmi changreu bantuk a si, a chunglei khur cu a fekmi ruh 8 nih aa pehtlaih i a dirpi, a cunglei Φ620 khur cu a chunglei khur he pehtlaihnak a tuah, cun a dang vialte cuvalvea khar ahcun, thetse hrampi cu remh a har i a rawk a fawi. Thli chuahnak le a chunglei khur thianhnak pahnih nih harnak nganpi a chuahpi, hmanthlak 1 ah hmuh khawh a si.

Casting pawl i an vampang a thuhnak cu aa dang ngai, a tam bik vampang a thuhnak cu 380mm a phan, cun a niam bik vampang a thuhnak cu 36mm lawng a si. Casting cu a fek tikah, lum le lum lo aa dannak cu a ngan, cun aa tluk lomi tlawmternak nih fawi tein tlawmternak khur le tlawmternak porosity tlamtlinlonak a chuahter khawh, cu nih cun hydraulic hneksaknak ah ti a luannak a chuahter lai.

2. Tuahning suaisamnak:

(1) A tthennak cunglei cu hmanthlak 1 ah hmuh khawh a si. A cunglei bawm cung ah a donghnak kha khur he chiah law, a laifang khur ah thetse hrampi dihlak ser, cun thetse hrampi hrennak le bawm cu aa mer tikah thetse hrampi cawlcangh khawhnak ding caah a hrampi lu kha aa tlak ning tein sauhter. A fekmi, a kam i a ummi mitcaw khur pahnih i an cantilever core lu saunak cu khur saunak nakin a sau deuh, cucaah thetse core dihlak i a ritnak hmun cu core lu lei ah aa hngat i thetse core cu a fekmi le a fekmi a si khawh nakhnga a tuah.

A tlawmpal a kharmi thletnak phunglam kha hman a si, ∑F chunglei: ∑F a tlarimi: ∑F a tlarimi=1:1.5:1.3, sprue nih a chunglei diameter Φ120 a simi ceramic tube a hman, cun thir kha direct in a lin lonak hnga 200×100×40mm a linmi lungtum pahnih kha a tanglei ah chiah a si sand mold, 150×150×40 foam ceramic filter cu runner tang ah chiah a si, cun a chunglei diameter Φ30 a ngeimi ceramic tubes 12 cu a chunglei runner caah filter tang ah ti khonnak tank in casting tang ah tlukruang tein pehtlaih khawhnak ding caah hman a si i, Esence scheme 2 ah langhtermi bantukin

(3) A cunglei thli khur 14 ∮20 chiah, a chung lu laifang ah Φ200 thetse core thli chuahnak khur chiah, a thukmi le a nganmi hmun ah thir lum chiah law thletmi thilri aa tluk tein a fek khawh nakhnga, cun graphitization kauhnak phunglam kha hmang law rawlchuannak kha a tthanchoter. Thetse bawm a ngan ning cu 3600×3600×1000/600mm a si, cun 25mm a thukmi thir tlawmpal in a tthawnnak le a fekmi a si khawh nakhnga an hren, hmanthlak 3 ah hmuh khawh a si.

3. Riantuan ning uknak

(1) Modeling: Model tuah hlanah, Φ50×50mm standard sample hmangin resin sand ≥ 3.5MPa a tthawnnak kha hneksak, cun a lummi thir le runner kha fek tein hren law sand mold nih a chuakmi graphite kha a tthawnnak a ngeih khawh nakhnga thir a alhmi chemical kauhnak le thir kha a tthawnnak in a kham khawh nakhnga caan saupi chung tliknak hmun nih thetse hnimhnak a chuahter.

Core sernak: Thetse core cu aa tlukmi tthen 8 ah tthen a si i, cu hna cu a laifang khur in an i pehtlaih. A laifang core lu ti lo ahcun a dang bawmtu le chuahnak thilri an um lo. Thetse hrampi cu remh khawh a si lo i Exhaust a si ahcun, thetse core thlennak le thli khur hna cu thlet hnu ah an lang lai. Thetse hrampi a dihlak in a kau caah, tthen riat ah tthen a si. A tthawngmi le a fekmi a ngeih a hau, cu nih cun vutcam a chuah hnu ah thetse hrampi a rawh lai lo, cun thlet hnu ah a rawk lai lo ti kha a hngalhter. A thlennak a chuak, cucaah thletnak vampang a thuhnak aa khatmi a si khawh nakhnga. Cu ruangah, a hleiin a hleiin core ruh pakhat kan ser, cun core ruh cungah thli luhchuahnak hri in kan hren i core lu in a chuakmi thli kha core ser tikah thetse mold a tlawm khawhnak hnga caah a si. Hmanthlak 4 ah hmuh khawh a si.

(4) Kharnak bawm: Butterfly valve chunglei khur chung i thetse thianh a har ti ruah tikah, thetse chung vialte cu rong tthen hnih in an suai, a hmasa bik tthen cu zu aa telmi zirconium rong (Baume degree 45-55) in an thuh, cun a hmasa bik tthen cu rong an suai i an khangh. A ro hnu ah, a pahnihnak tthen cu zu-hram bunhmi magnesium rong (Baume degree 35-45) in rong, cu nih cun a thletmi cu thetse ah aa hngat lo i a thianh khawh lomi a lum lo. A hrampi lu tthen cu a hrampi ruh a hrampi sining Φ200 thir pipe cungah M25 hri pathum in an thlai, a cunglei mold thetse bawm he hri khuhnak he an hren i an khar i tthen pakhat cio i an vampang a thuhnak aa khat maw ti kha an zoh.

4. Hnimhnak le thletnak kalning

(1) Benxi low-P, S, Ti ttha Q14/16# vok thir hmang law, 40%~60% tluk in cawh; P, S, Ti, Cr, Pb, tbk. tibantuk thilri hna cu thir hlonhmi ah fek tein uk an si, cun vutcam le chiti hman khawh a si lo, chapmi zat cu 25%~40% a si; a kirtermi charge cu hman hlanah meithal kahnak in thianh a hau, cu nih cun charge a thianhlimnak kha a hngalhter lai.

(2) Furnace hnu ah a biapi bikmi thilri uknak: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (a tangmi): 0.035% ~0.05%, a tanglei ah a ummi, a tanglei ah a ummi, a tanglei ah a ummi, a tanglei ah a ummi, a tanglei ah a ummi. a niam deuhmi Mg (a tangmi) kha a si khawh chungin din ding a si.

(3) Spheroidization inoculation thlopnak: low-magnesium le low-rare-earth spheroidizers hman a si, cun chapnak ratio cu 1.0%~1.2% a si. A hlan bantuk in thianhnak phunglam in spheroidization thlopnak, voikhat hmanmi 0.15% cu package tang ah a ummi nodulizer cungah a khuh, cun spheroidization cu a dih. Cu hnuah slag cu 0.35% a changtu thlopbulnak caah subcontract tuah a si, cun thlet lio ah 0.15% a luangmi thlopbulnak tuah a si.

(5) A niam mi lumternak rang tein thletnak phunglam kha hman a si, thletnak lumnak cu 1320°C~1340°C a si, cun thletnak caan cu 70~80s a si. A lummi thir cu thlet lio ah a rawk kho lo, cun sprue hrai cu a khat zungzal i cu nih cun gas le aa telmi thilri pawl kha runner in thir chungah an i tel lonak hnga a kham. khur.

5. Casting hneksaknak phichuak

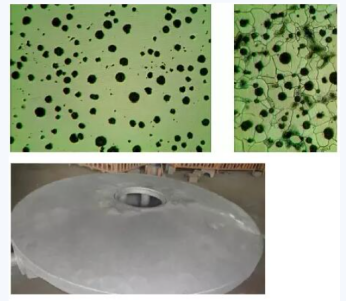

(1) Cast test block i a tthawnnak kha hneksak: 485MPa, a sauhnak: 15%, Brinell harnak HB187.

(2) Spheroidization rate cu 95% a si, graphite a ngan ning cu grade 6 a si, cun pearlite cu 35% a si. Thir suaisamnak sining cu hmanthlak 5 ah hmuh khawh a si.

(3) UT le MT a biapi mi thilri hna i a pahnihnak palhnak hmuhnak ah ttial khawhmi tlamtlinlonak pakhat hmanh hmuh a si lo.

(4) A muisam cu a tlarimi le a nemmi a si (Hmanthlak 6 zoh), vutcam aa telmi, vutcam aa telmi, a kikmi kharnak tibantuk thletnak tlamtlin lonak a um lo, vampang a thuhnak cu aa khat, cun a kauh ning cu suaimi thilri hna nih an herhmi a tlinh.

(6) 20kg/cm2 hydraulic pressure hneksaknak tuah hnu ah a luangmi a um lo

6. Biadonghnak

Hi butterfly valve i a sining ning in, a laifang ah a ummi thetse nganpi a fek lomi le fawi tein aa thleng khomi le thetse thianhnak a harmi cu thil kalning timhtuahnak suaisamnak, thetse core chuah le remhnak le zirconium-based coatings hmannak ah biapi chiahnak in a tawlrel. Thli chuahnak khur pawl chiahnak nih thil thletnak ah a ummi khur pawl a hrial. Furnace charge control le runner system in, foam ceramic filter screen le ceramic ingate technology cu a lummi thir thianhlimnak hngalh khawhnak caah hman a si. Sii thlopnak voi tampi tuah hnu ah, thir tthencheunak le a phunphun a tlingmi riantuan ning nih cun a cawtu hna nih an herhmi a phan cang

Mah in hinTianjin Tanggu Ti-kharnak valve Co.,ltd. Butterfly valve, kutka valve, Y-strainer, wafer dual plate check valvesernak.

Post caan: Apr-29-2023