A ttha ngaimi Backflow khamnak

A tthangcho bikmi thilchuahnak thilri, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak uknak system le hawikomhnak a ngeimi thiamsang zuarnak phu nih tthatnak sang Backflow Preventer caah zuar hlan/hnu bawmhnak kan ngei, lungthin tak tein le thazaang kan ngei, a caan ah cohlanmi a ttha deuhmi tthatnak kha kan kilven, kan factory ah kan in don hna i company le cawnpiaknak caah kan in don hna.

A tthangcho bikmi thilchuahnak thilri, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak zohkhenhnak system le hawikomhnak a ngeimi thiamsang zuarnak phu zuar hlan/hnu bawmhnak kan ngeiTuluk Check Valve le Valve, Vawleicung pumpi ah kan riantuan hawi hna an halmi tlinter kan i zuam. Kan thilri le riantuannak phunphun cu a cawtu hna herhmi tlinter awkah a karh peng. Hmailei chawlehnak pehtlaihnak le pakhat le pakhat hlawhtlinnak hmuh khawhnak ding caah nunphung kip in a thar le a hlun hna nih kanmah he pehtlaihnak tuah dingin kan in don hna!

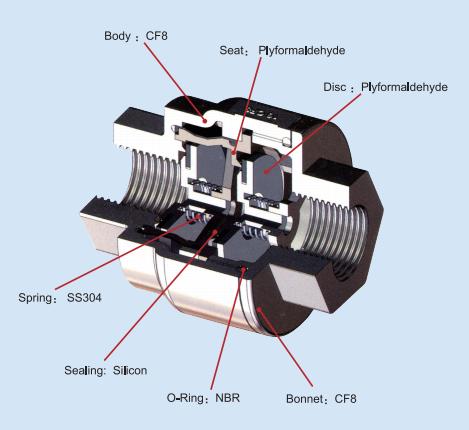

Langhtermi:

Khuami tam deuh nih cun an ti pipe ah backflow khamnak thilri an bunh lo. Mi tlawmte lawng nih hnulei-tlawm khamnak caah a tlangpi in check valve an hman. Cucaah ptall nganpi a ngei lai. Cun backflow khamnak phun hlun cu a man a fak i ti chuah a fawi lo. Cucaah hlan ahcun tam deuh in hman a rak har ngai. Asinain a tu cu, a dihlak in tawlrel khawhnak ding caah phun thar kan ser. Kan anti drip mini backlow khamnak cu a hmangmi hna caah tampi hman a si lai. Mah cu ti thazaang uknak fonhmi thilri a si i, pipe chung i a ummi hneknak kha uknak thawngin lam pakhat lawng a luangmi a si. A hnulei a luangmi kha a kham lai, ti tahnak kha a hnulei ah a kirter lai i a luan lonak ding caah a kham lai. Din awk ti thiang a pek lai i thurhnawmhnak a kham lai.

Mah sining a langhtertu:

1. A tlarimi sotted density suaisam, a niam mi luannak doh khawhnak le a niam mi aw.

2. A hmete, a tawi, chiah a fawi, chiahnak hmun a tlawm.

3. Ti meter thlennak le a sang deuhmi anti-creeper idling riantuannak kha kham,

ti tlawmte lawng a thletmi nih ti zohkhenhnak ah a bawmh.

4. Thimmi thilri hna cu caan saupi hman khawhnak an ngei.

Riantuannak phunglam:

Threeded chungin check valve pahnih in sermi a si

pehtlaihnak.

Mah cu lam khatlei a luangmi a tlin khawhnak ding caah pipe chung i a ummi hneknak kha uk khawhnak thawngin ti thazaang uknak fonhmi thilri a si. Ti a rat tikah, disc pahnih cu an on lai. A dir tikah, a hri nih a khar lai. A hnulei a luangmi kha a kham lai i ti meter kha a hnulei ah a kirter lai lo. Hi valve nih hin thatnak dang pakhat a ngei: A hmangtu le Ti Peknak Corporation karlak ah a dikmi a si lai ti a hngatchan. A luannak cu a tlawm tuk caah (cu bantuk: ≤0.3Lh), hi valve nih hi thil sining hi a tawlrel lai. Ti thli thlennak ning in, ti tahnak cu aa mer.

Chiahnak:

1. Insalation tuah hlanah pipe kha thianh hmasa.

2. Hi valve hi a tlarimi le a tlarimi in chiah khawh a si.

3. Install tuah tikah a tlawmbik a luannak lei le thal lei cu aa khatmi siter.

A kauh ning:

A tthangcho bikmi thilchuahnak thilri, hmuhtonnak a ngeimi le thiamnak a ngeimi engineer le riantuantu, theihhngalhmi tthatnak uknak system le hawikomhnak a ngeimi thiamsang zuarnak phu nih tthatnak sang Backflow Preventer caah zuar hlan/hnu bawmhnak kan ngei, lungthin tak tein le thazaang kan ngei, a caan ah cohlanmi a ttha deuhmi tthatnak kha kan kilven, kan factory ah kan in don hna i company le cawnpiaknak caah kan in don hna.

A tthatnak sangTuluk Check Valve le Valve, Vawleicung pumpi ah kan riantuan hawi hna an halmi tlinter kan i zuam. Kan thilri le riantuannak phunphun cu a cawtu hna herhmi tlinter awkah a karh peng. Hmailei chawlehnak pehtlaihnak le pakhat le pakhat hlawhtlinnak hmuh khawhnak ding caah nunphung kip in a thar le a hlun hna nih kanmah he pehtlaihnak tuah dingin kan in don hna!