Ductile iron Static Balance Control Valve

Ductile thir Static Balance Control Valve caah sernak chung ah tthatnak thlennak hmuh le ramchung le ramleng cawtu hna caah lungthin dihlak in bawmhnak ttha pek kan timh, hmailei ah kan i zuamnak thawngin nanmah he a sunglawi deuhmi hmailei kan ser khawh lai tiah ruahchannak kan ngei.

Sernak chung ah tthatnak thlennak hmuh kan timh i ramchung le ramleng cawtu hna caah lungthin dihlak in bawmhnak ttha bik pek kan timhaa thleng lomi tlukruannak valve, Kan thilri pawl cu vawleicung pumpi ah kuat an si. Kan riantuanpi hawi hna cu kan zumhawktlakmi thilri, riantuanpi hawi he aa pehtlaimi riantuannak le zuamnak man ah an lung a tling zungzal. Kan rian cu “kan thilri le riantuannak hna tthanchoter pengnak ah kan thazaang peknak thawngin nan zumhtlak sinak hmuh peng ding a si, cu nih cun kan hmanmi hna, kan cawtu hna, riantuantu hna, thilri a kan petu hna le kan i bawmhchanhnak vawleicung pumpi zatlangbu hna lungtlinnak hmuh khawhnak ding caah a si”.

Langhtermi:

TWS Flanged Static balancing valve cu HVAC hmannak ah ti pipeline system a dikthliar in a luan ning uknak caah hmanmi a biapi mi hydraulic balancing thilri a si i ti system dihlak ah static hydraulic balance a um khawhnak hnga caah a si. A tthencheunak nih cun terminal thilri le pipeline pakhat cio i a luan ning taktak kha a luan ning tahnak computer he hmunhma riantuannak ah system hramthawk riantuannak ah suaisam luan ning he aa tlak in a hngalhter khawh. HVAC ti system ah a tlangpi pipe, branch pipe le terminal thilri pipeline ah series pawl cu tam deuh in hman an si. Cun riantuannak a herhmi aa khatmi application dang zongah hman khawh a si.

Hmai chung thil

A fawimi pipe suaisam le tuaktannak

A rangmi le a fawimi chiahnak

Tahnak computer hmangin hmunhma chung ti a luan ning tah le tawlrel a fawi

Hmun ah aa dangmi hneknak tah a fawi

Digital presetting le hmuh khawhmi presetting langhternak he stroke rikhiahnak in tlukruannak tuah

Aa dangmi hneknak tahnak caah hneknak hneksaknak cock pahnih he aa thuammi Riantuannak fawi deuh caah a kai lomi kut kedan

Stroke khamnak-screw cu huhphenhnak lukhuh nih a huhphenh.

Valve stem cu thir SS416 in sermi a si

Epoxy powder in a rawk kho lomi suaimi thir pum

Soknak:

HVAC ti system

Chiahnak

1.Hi lamhruainak hna hi ralring tein rel. An zulh lonak nih thilri a hrawh khawh asiloah tihnung dirhmun a chuahter khawh.

Na hmanmi thilri he aa tlak maw tlak lo ti hngalh awkah lamhruainak le thilri cung i pekmi tahfung kha zoh.

3.Installer cu cawnnak a ngeimi, hmuhtonnak a ngeimi riantuannak a ngeimi a si lai.

4.Installation a dih tikah ttha tein zohfelnak tuah zungzal.

Thilri kha harnak um loin hman khawhnak ding caah, chiahnak phunglam ttha ah a hramthawk ah system thianhnak, chemical ti thianhnak le 50 micron (asiloah a ttha deuhmi) system lei stream filter(s) hmannak aa tel a hau. Na thlet hlanah filter vialte kha hloh dih hna. 6.A hramthawknak system thianhnak tuah awkah a hlankan in hmanmi pipe hman ding in ruahnak cheuh. Cun pipe chung i valve kha hnimh.

Boiler additives, solder flux le wetted materials hna cu petroleum hrambunhmi asiloah mineral oil, hydrocarbons, asiloah ethylene glycol acetate aa telmi hna kha hmang hlah. A tlawmbik 50% ti cawh in hman khawhmi thilri hna cu diethylene glycol, ethylene glycol, le propylene glycol (antifreeze solutions) an si.

Valve cu valve pum cung i a ummi thal he aa khatmi a luannak lei ah chiah khawh a si. A dik lomi chiahnak nih hydronic system a rawk lai.

Thil chiahnak kuang chungah hneksaknak cock pahnih aa peh. A hramthawk riantuannak le thianhnak hlan ah chiah a si lai ti kha i cinken. Install tuah hnu ah a rawk lo ti kha zohfel.

A kauh ning:

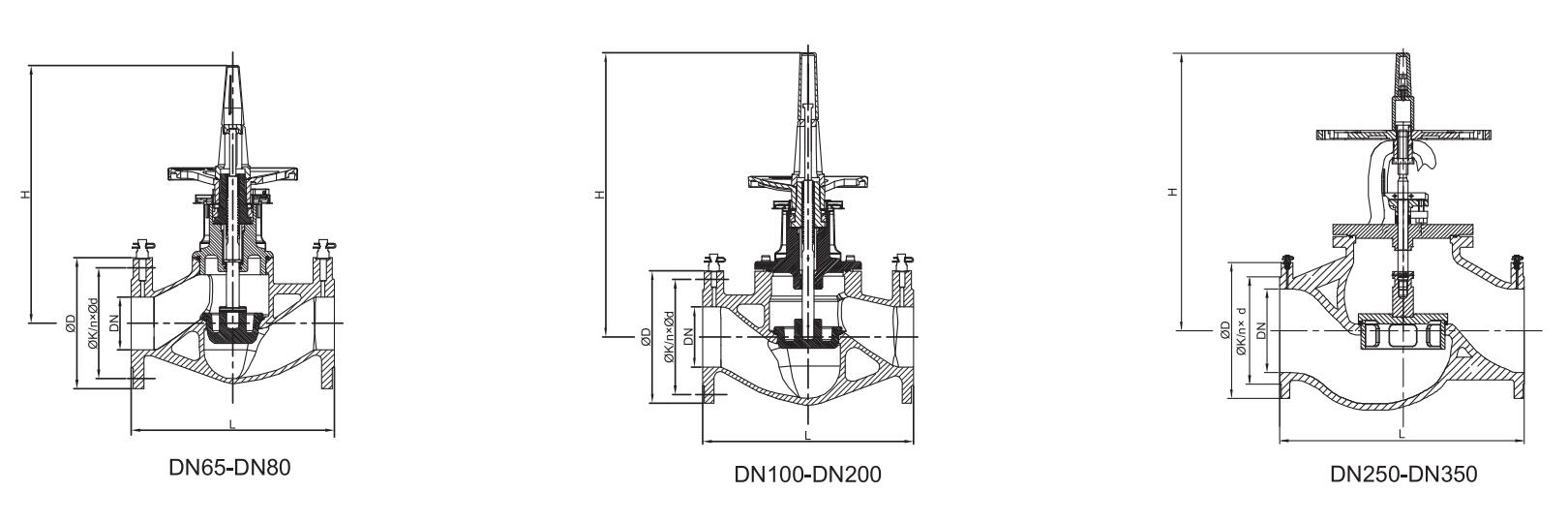

| DN | L | H | D | K | n*d |

| 65 | 290 | 364 | 185 | 145 | 4*19 |

| 80 | 310 | 394 | 200 | 160 | 8*19 |

| 100 | 350 | 472 | 220 | 180 | 8*19 |

| 125 | 400 | 510 | 250 | 210 | 8*19 |

| 150 | 480 | 546 | 285 | 240 | 8*23 |

| 200 | 600 | 676 | 340 | 295 | 12*23 |

| 250 | 730 | 830 | 405 | 355 | 12*28 |

| 300 | 850 | 930 | 460 | 410 | 12*28 |

| 350 | 980 | 934 | 520 | 470 | 16*28 |

Sernak chung ah tthatnak thlennak hmuh kan timh i ramchung le ramleng cawtu hna caah Balance Valve caah lungthin dihlak in a ttha bikmi bawmhnak pek kan timh, hmailei ah kan i zuamnak thawngin nanmah he a sunglawi deuhmi hmailei kan ser khawh lai tiah ruahchannak kan ngei.

A ttha ngaimi Valve he aa zuammi man, Kan thilri pawl cu vawleicung pumpi ah kuat an si. Kan riantuanpi hawi hna cu kan zumhawktlakmi thilri, riantuanpi hawi he aa pehtlaimi riantuannak le zuamnak man ah an lung a tling zungzal. Kan rian cu “kan thilri le riantuannak hna tthanchoter pengnak ah kan thazaang peknak thawngin nan zumhtlak sinak hmuh peng ding a si, cu nih cun kan hmanmi hna, kan cawtu hna, riantuantu hna, thilri a kan petu hna le kan i bawmhchanhnak vawleicung pumpi zatlangbu hna lungtlinnak hmuh khawhnak ding caah a si”.