DN50-300 Composite high speed Air release valves in Casting Ductile Iron GGG40 , PN10/16

Kan tthatnak tthatnak phu nganpi chungin chungtel pakhat cio nih 2019 caah zuarnak man ductile iron caah riantuanpi hawi hna herhmi le bu pehtlaihnak kha an sunsakThli Chuahnak Valve, Kan zuar hlan le zuar hnu riantuannak ttha he fonh in a ttha ngaimi a phichuak hmuh pengnak nih vawleicung pumpi ah a karh chin lengmangmi chawlehnak hmun ah zuamnak fek a chuahter.

Kan tthatnak hlawknak phu nganpi chungin chungtel pakhat cio nih riantuanpi hawi hna herhmi le bu pehtlaihnak kha an sunsakThli Chuahnak Valve, Ramdang le ramchung mi hna lakah minthatnak kan hmuh. “Credit lei ah aa hngatmi, a cawtu hmasa, riantuan ning a sangmi le a tthangchomi riantuannak” timi hruainak phunglam kha zulh in, kanmah he riantuan tti dingin nunning kip in hawikom hna kha lunglawm tein kan don hna.

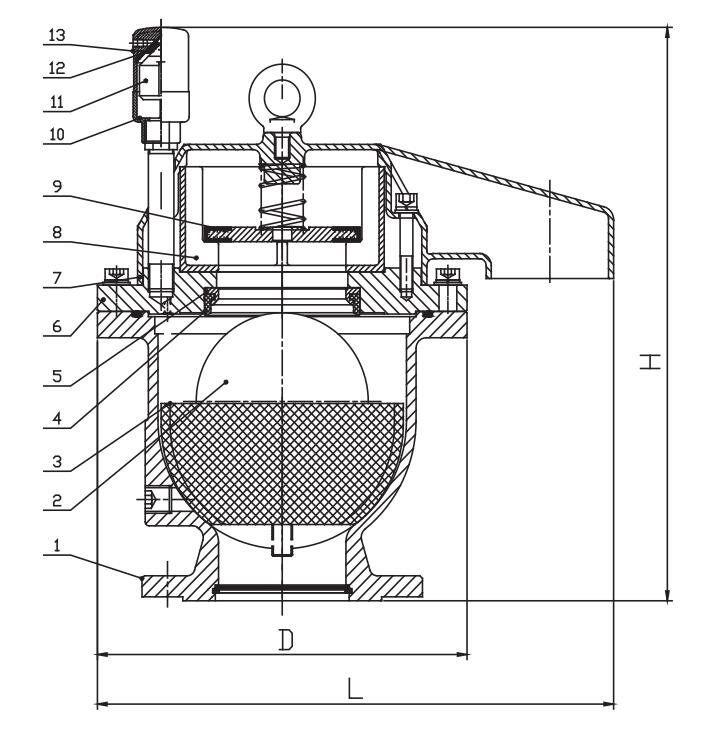

Langhtermi:

A rang tukmi thli chuahnak valve cu a sangmi diaphragm thli valve tthen hnih le a niammi luhnak le chuahnak valve he fonh an si, a chuahnak le a luhnak riantuannak pahnih a ngei.

A tthawngmi diaphragm thli chuahnak valve nih pipeline cu pressure tangah a um tikah pipeline chung i a khonmi thli tlawmte kha amah tein a chuahter.

A tlawmmi hneknak laknak le chuahnak valve nih a lawngmi pipe cu ti in a khat tikah pipe chung thli kha a chuahter khawh lawng si loin, pipe cu a thiang lo asiloah a ttha lomi hneknak a chuah tikah, ti column tthennak dirhmun tangah tibantuk ah, amah tein aa hun lai i a ttha lomi hneknak kha hloh awkah pipe chungah a lut lai.

Thli chuahnak valve rian nganbik pakhat cu system chungin a tlaumi thli chuahter kha a si. Ti cu pipe chungah a luh tikah, thli cu a sang deuhmi hmun, a tliknak, a sangmi hmun le tlangpar tibantuk ah a tla kho. Pipe chungin ti a luan tikah, thli cu aa pum kho i thli kuang a ser khawh, cu nih cun riantuan khawhnak a zorter khawh i a tthawnter khawh.

TWS Valve dang bantuk in thli chuahnak valverubber in a tthumi hlinghro vavlves, zong nih ti a phurtu pipe le system hna tthatnak le tluang tein riantuan khawhnak ah a biapi tukmi rian an ttuan. A tlaumi thli chuah khawhnak le vacuum dirhmun kham khawhnak nih system riantuan ning a ttha bik in a tuah khawh, hnahnawhnak le rawhralnak a kham khawh. Thli chuahnak valve a biapitnak hngalhthiamnak le aa tlakmi chiahnak le zohkhenhnak tuahsernak tuahnak thawngin, system riantuantu hna nih an pipe le system hna nun saunak le zumhawktlak sinak kha an hngalh khawh.

Riantuannak caah a herhmi:

A tlawmmi thli chuahnak valve (float + float phun) thli chuahnak hmun nganpi nih thli cu a rang tukmi thli chuahnak ah a lut i a chuah khawhnak hnga a tuah, a rang tukmi thli chuahnak hmanh ah ti thli he cawhmi, thli chuahnak hmun kha a hlankan in a khar lai lo. Vanlawng chuahnak hmun cu thli a chuah dih hnu lawngah khar a si lai.

Zeitik caan paoh ah, system chunglei hneknak cu thli hneknak nakin a niam deuh chung paoh cu, tahchunhnak ah, ti tthennak a chuah tikah, thli valve cu system chung i thli luhter awkah a hun colh lai i cu nih cun system chung i vacuum a chuahter lai lo. Cu lio caan te ah cun, system a thlet lio ah thli a caan hmaan tein laknak nih thli chuah rangnak a rangter khawh. Exhaust valve cunglei cu exhaust kalning a nemtertu dingah a hnahnawhnak a kham khomi tlawmpal he aa thuam, cu nih cun pressure aa thleng lengmangmi asiloah a dang rawhralnak thil a kham khawh.

A tanglei thil sining hna hrial khawhnak dingah system chung i a sangmi hmun ah a tlummi thli kha system cu pressure tangah a um lio ah a chuahter khawh: thli kharnak asiloah thli kharnak.

System lu tlaunak karhternak nih a luannak a zorter i a zual tukmi thil sining hmanh ah ti phorhnak kha a dihlak in a ngolter khawh. Cavitation rawhralnak kha fak deuh in tuah, thir thilri hna i rawhnak kha rang deuh in tuah, system chung i pressure thlennak kha karhter, tahnak thilri palhnak kha karhter, le gas puahnak kha karhter. Pipeline riantuannak ah ti peknak tthatnak tthanchoter.

Riantuannak phunglam:

A lawngmi pipe cu ti in a khat tikah fonhmi thli valve riantuan ning:

1. Ti tling tein a kal khawh nakhnga pipe chung thli kha chuah.

2. Pipeline chung i thli cu a dih hnu ah, ti cu a niammi luhnak le chuahnak valve ah a lut, cun a luhnak le chuahnak hmun pawl kha khar awkah a luangmi nih a cawi.

3. Ti pekchanhnak tuah lio ah ti chungin a chuakmi thli cu system a sang bik hmun ah lak a si lai, cucu, thli valve chungah valve pum chung i a hramthawk ti aiawhtu ah lak a si lai.

4. Thli a khon tikah, a sangmi micro automatic chuahnak valve chung i ti tlawmtam cu a tla, cun a luangmi ball zong a tla ve, diaphragm kha khar awkah a hnuh, thli chuahnak khaan kha a hun i thli kha a chuahter.

5. Thli a chuah hnu ah, ti cu a fakmi micro-automatic chuahnak valve chungah a lut ṭhan, a luangmi ball kha a hler, cun thli chuahnak khar kha a khar.

System a kal lio ah, a cunglei 3, 4, 5 step pawl cu a kal peng lai

System chung i a ummi hneknak cu a niam i thli hneknak (negative pressure a chuahtertu) a si tikah fonhmi thli valve riantuan ning:

1. A tlawmmi thli luhnak le chuahnak valve i a luangmi ball cu a tla colh lai i luhnak le chuahnak port pawl kha a hun lai.

2. Hi hmun in thli cu a ttha lomi hneknak hloh awk le system kilven awkah system chungah a lut.

A kauh ning:

| Thilri phun | TWS-GPQW4X-16Q | |||||

| DN(mm) | DN50 | DN80 | DN100 | DN150 | DN200 | |

| Kauhning (mm) | D | 220 | 248 | 290 | 350 | 400 |

| L | 287 | 339 | 405 | 500 | 580 | |

| H | 330 | 385 | 435 | 518 | 585 | |

Kan tthatnak hlawknak phu nganpi chungin chungtel pakhat cio nih 2019 caah zuarnak man ductile iron Air Release Valve caah a cawtu hna herhmi le bu pehtlaihnak kha an sunsak, Kan zuar hlan le zuar hnu riantuannak ttha he fonh in a ttha ngaimi a phichuak hmuh pengnak nih vawleicung pumpi ah a karh chin lengmangmi chawlehthalnak hmun ah zuamnak fek a chuahter.

2019 zuar manTuluk thli chuahnak valvele Betterfly Valve, Ramdang le ramchung mi hna lakah minthatnak kan hmuh. “Credit lei ah aa hngatmi, a cawtu hmasa, riantuan ning a sangmi le a tthangchomi riantuannak” timi hruainak phunglam kha zulh in, kanmah he riantuan tti dingin nunning kip in hawikom hna kha lunglawm tein kan don hna.